Quality management

To ensure that our products meet the requirements of our customers, we work in quality assurance with the highest precision measurement technology.

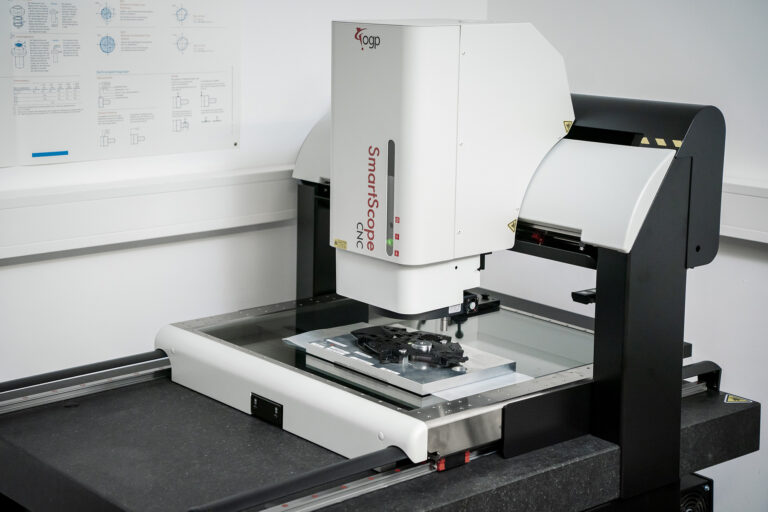

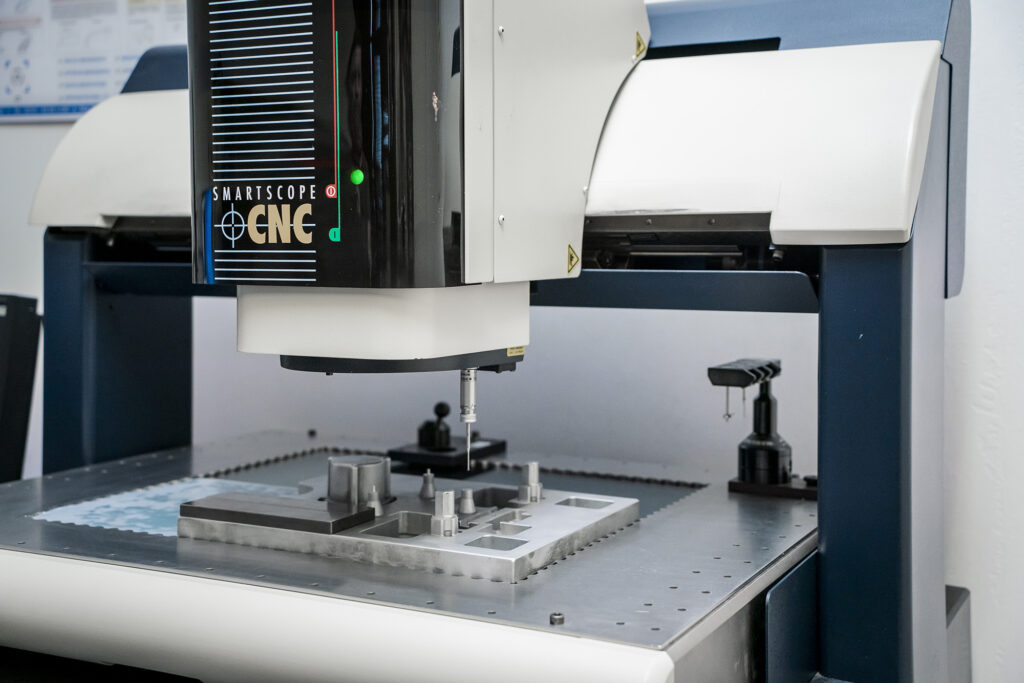

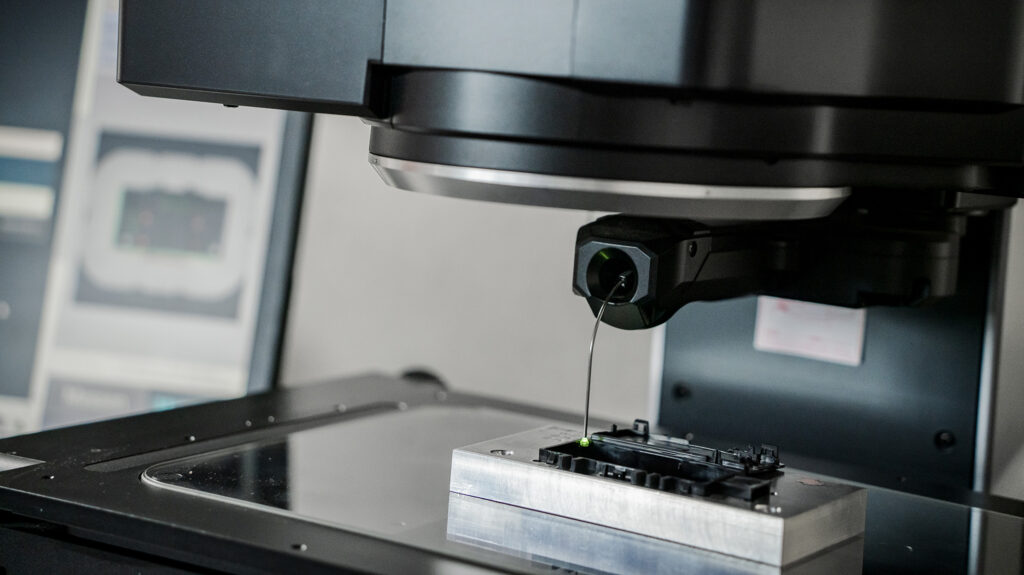

The OGP CNC 3D multi-sensor measuring system offers perfect quality control through the possibility of optical and/or tactile measurement of the object. The precision optics with zoom lens of the OGP Smartscope CNC 500 is mounted on a bridge structure and guarantees absolute measuring stability. In addition, scanning and laser orientation points ensure special accuracy.

Keyence measuring projectors perform accurate measurements. Various functions ensure that measurements remain constant and that results are fast, automated and reliable.

CT initial measurement in the accredited laboratory.

- Minolta colour measurement technology with spectrophotometers.

- Light chamber with defined light classes for colour assessment.

- Production-accompanying, variable and attributive testing CAQ system Böhme & Weihs (process capability) are of great importance for quality assurance by monitoring compliance with quality targets and quality-relevant processes.

- Lean and Six Sigma expertise

- In the continuous improvement process (CIP), product, process and service quality is constantly improved through teamwork and is an integral part of ISO 9001. In addition, TPM (Total Productive Maintenance) is used in all areas of the company in order to avoid downtimes, quality losses etc.