Finishing

A wide range of finishing options gives the products their final design.

Depending on the required design or the application of the end product, the surface is processed or finished after completion of the plastic part. For this, we draw on our portfolio of in-house solutions or work with well-established external partners who take over individual finishing steps under our control and responsibility as required.

Whether painting, laser marking, printing or coating: we offer a variety of finishing processes such as multi-colour printing up to 5 colours in a single operation.

Printing

Many ways to decorate surfaces.

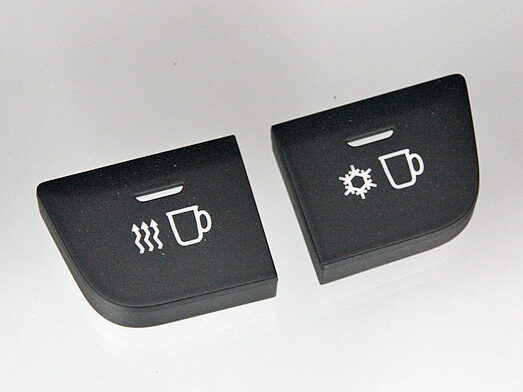

We offer printing on injection-moulded plastic parts for the precise application of lettering or symbols in up to five colours using pad or screen printing. Thanks to the use of flexible printing pads that adapt perfectly to the surface, even uneven surfaces can be printed.

We have two fully automatic printing machines that enable 5-colour large series printing and therefore guarantee fast and efficient production of large quantities. We also have two semi-automatic machines for 2-colour printing of small and medium-sized series.

If required, additional varnishing for special scratch resistance is also possible.

Our automation and tray handling guarantee smooth production and the highest quality of our printed plastic parts.

Lacquer finish

Two coordinated building blocks of our competence

Aesthetics and function are increasingly required in the automotive industry as well as in other industrial sectors such as consumer goods or “white goods”. In surface design, special effects can be achieved in terms of appearance (colouring, gloss level from matt to high gloss), feel (smooth to soft or textured) and function (scratch resistance, chemical resistance, UV resistance).

The lacquering of our own injection-moulded products is an integral part of our range. We master both processes -separately from each other- and coordinate them precisely. A high-quality injection moulded part is the best prerequisite for a high-quality painted end product.

With our extensive knowledge of plastics and their decoration possibilities, we support product design and optimise the economic efficiency of the production chain. We always find the best combination of plastic type and lacquer to meet our customers’ requirements. We already take the next finishing steps into account during the design phase and mould construction. A precise and efficient production process serves to reduce waste.

The lacquering is carried out by a team of experienced specialists who are equipped with the latest technology to guarantee a perfect result in the required quality. The lacquers selected and used are very versatile depending on the requirements: whether water/solvent-based or UV-cured, they generally ensure that the component is enhanced.

Chrome plating

Plastic parts with a metallic look are playing an increasingly important role in many industries. Chromium plating using the PVD (Physical Vapour Deposition) coating process is a special environmentally friendly type of metallisation. Alternatively, electroplating with Cr³+ is possible. Metallic effects with chrome are not only visually very appealing, but can also have a function in that they form a protection against corrosion and at the same time increase the surface quality.

Laser marking

Flexible, efficient and durable marking.

Laser marking is a sustainable and tamper-proof alternative to adhesive labelling. It is particularly suitable wherever there is little space available, as the permanent inscription can be applied at the same time as fine as a hair and razor-sharp – even on curved areas. The inscription can be created either by colour removal or colour change.

For example, in the case of control elements, the removal of colour and/or material makes the base material visible again and can be backlit if necessary. In the case of colour change, the material changes colour due to the local heating/destruction of the laser beam. The surface remains intact and smooth. Consecutive numbering is indeed possible with laser technology.

Hard coating

High scratch resistance and high-quality appearance.

The special coating has highly transparent properties and is therefore ideal for visually and functionally demanding surfaces. It is characterised by its high clarity, light transmission and UV resistance, which ensures effective protection of transparent, painted or coloured injection-moulded parts. This coating is particularly suitable for use in vehicle interiors or for operating surfaces such as sensors, front modules and optical parts.