Tray system

The ideal solution for efficient and safe handling of your plastic components.

Our tray system has been specially developed for the production, transport and product handling of plastic components. With a wide range of features and functions, the tray system can be optimally customised to your needs.

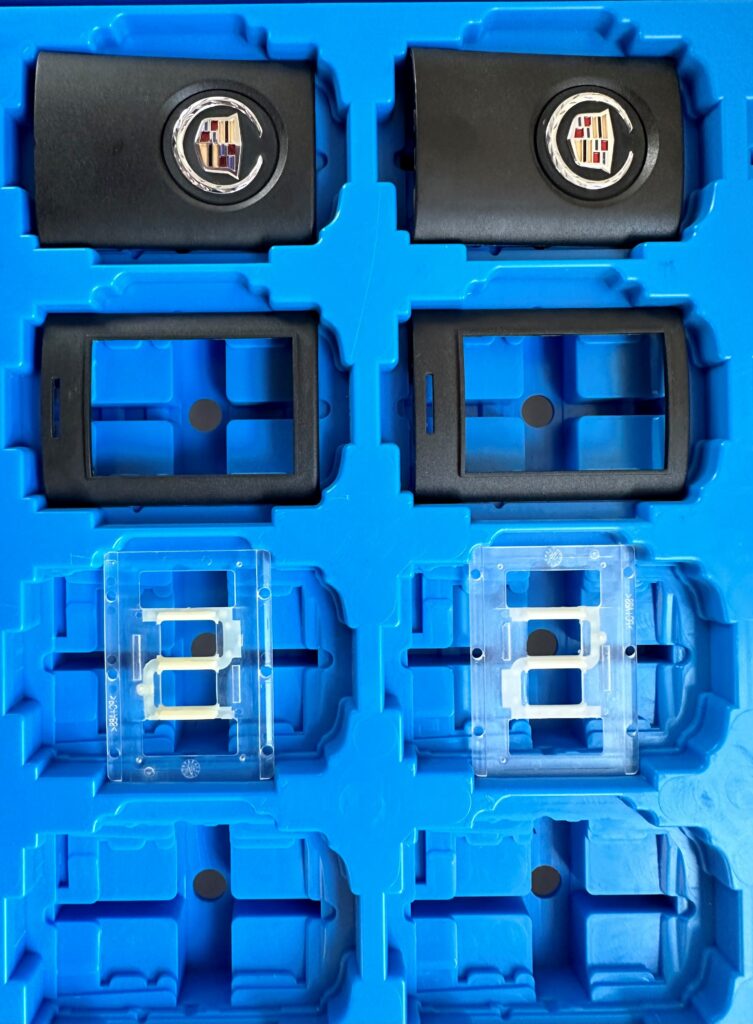

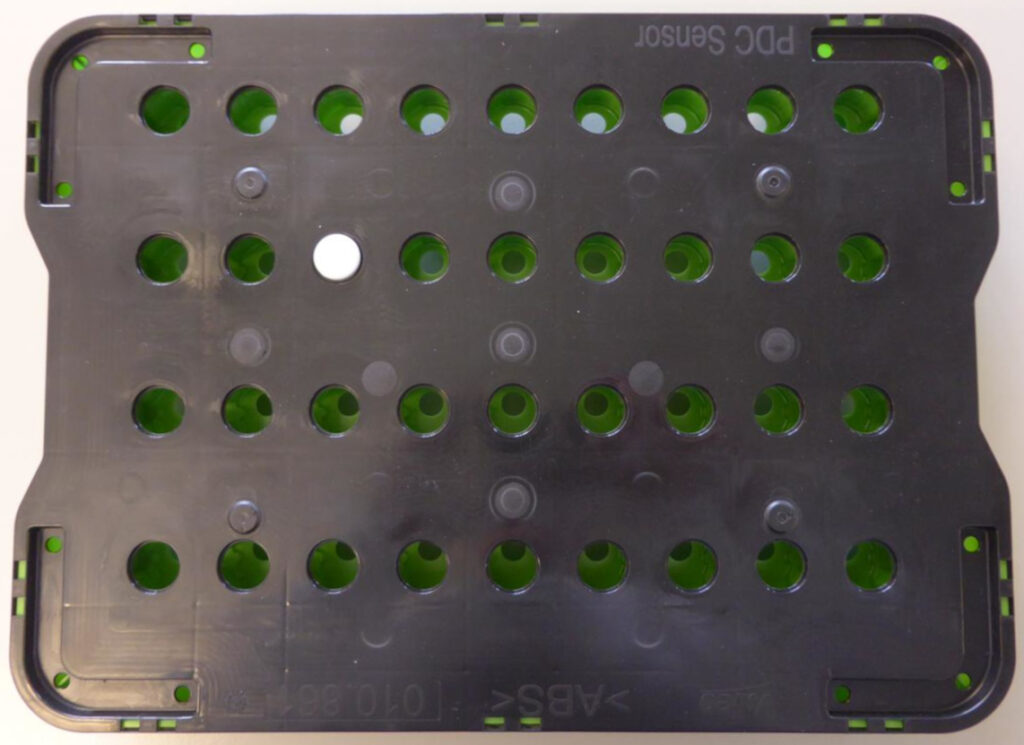

Depending on the requirements and planned use, the choice of suitable material is almost unlimited. From low-cost regranulate to heavy-duty ABS can be used. The tray is also available in various conductive, non-conductive, ESD and non-ESD versions.

Another major advantage of the tray system is its flexibility. Each individual part has a unique position, which leads to a reduction in the variety of trays and is therefore more cost-effective. By taking into account various geometric features and optimum position orientation, the parts can be optimally accommodated in the tray. Undercuts and cut-outs are possible, as is storage in different levels.

The customised geometry and the different levels enable a variety of uses for different parts with a single tray.

The tray system is stackable and has external dimensions,

which are adapted to KLT (small load carriers).

The tray system is available in various sizes to meet individual application requirements. In addition, the tray system can be supplied in almost any colour to enable simple and effective identification of article groups.

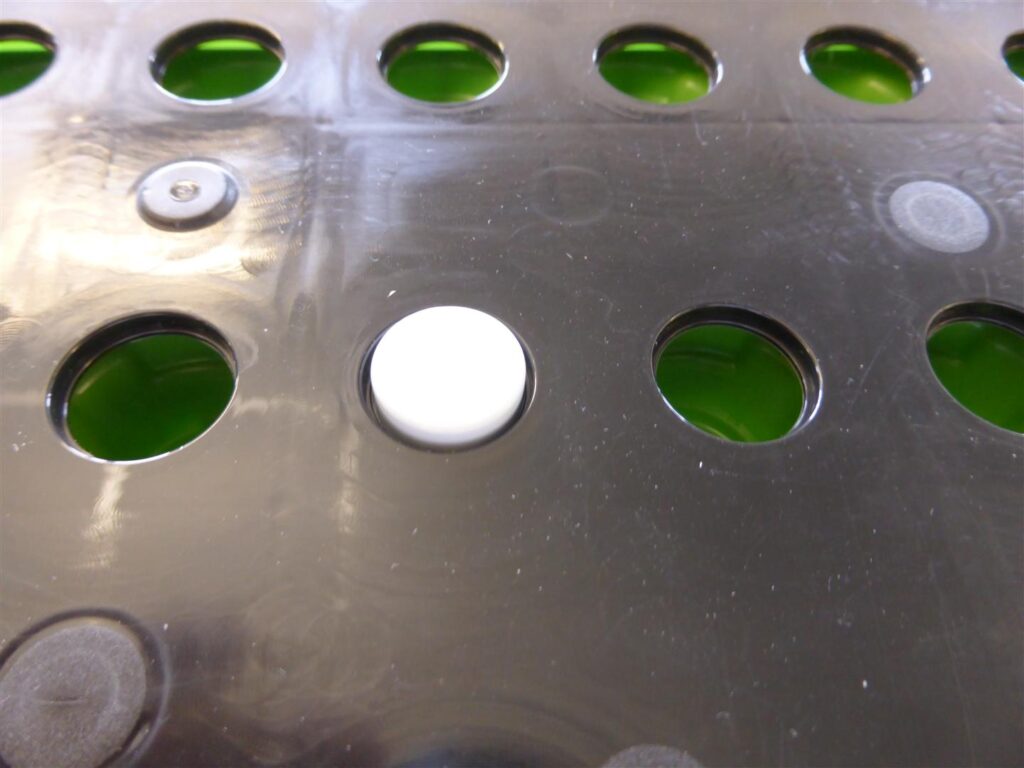

Different plastics can be used in a tray during production using the 2K process. For example, ABS can be combined with TPE to integrate rubber linings, buffers, sealing lips or latching functions. This means that the individual parts are protected during transport or for finishing and stored in a non-slip and dust-proof manner. For even safer transport in an ABS tray, the use of a suitable latching lid is recommended, which is also suitable for automatic finishing.

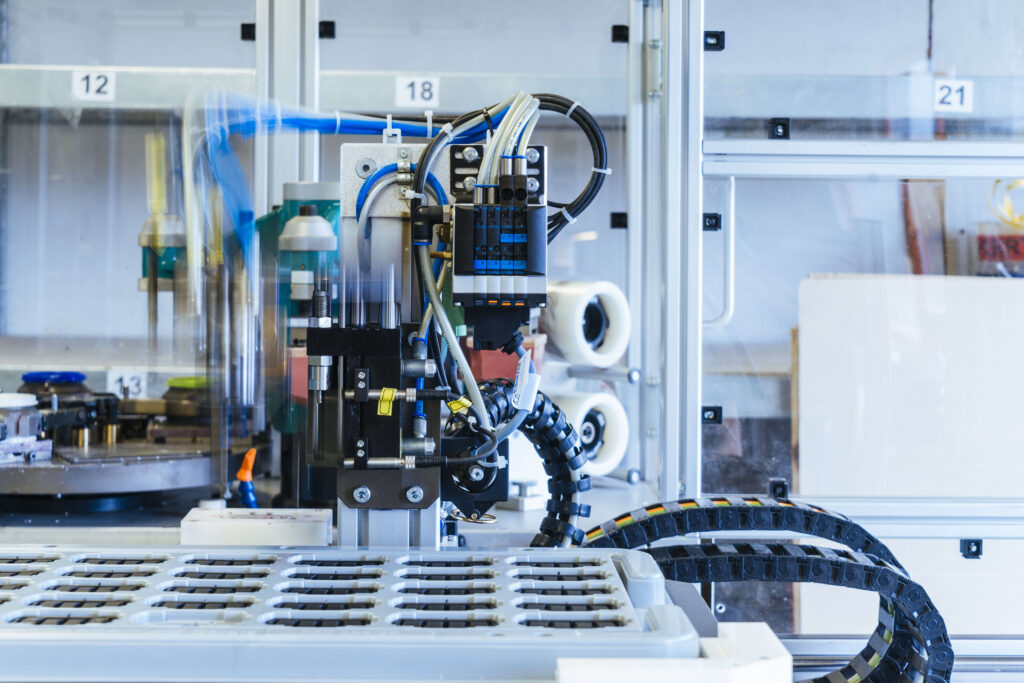

The tray system can be perfectly integrated into automated processes thanks to the very tight position tolerance, among other things. The high positioning accuracy and the possibility of product alignment on strips facilitate placement on the trays. It is suitable for automatic finishing and enables both automatic and manual assembly processes. For example, the assembly of safety mats and contact fields can take place directly in the tray.

The customisation options for wall thicknesses and geometry ensure a high degree of dimensional stability for our workpiece carriers. The inner and outer contours can be designed differently. The system is also mechanically resilient, wear- and impact-resistant, self-lubricating and corrosion-resistant. It is completely maintenance-free and can be sterilised or antibacterially treated.